bespoke Evaporation Residue Testing|100 degree evaporation residue : bulk This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, aerospace, and other industries. . EIN and ITIN are also accepted. Account number. Email

{plog:ftitle_list}

WEB9 de fev. de 2023 · 866K subscribers. 4.9K views 1 month ago. Check out the new The Consultant Season 1 Trailer starring Christoph Waltz! Learn more: .

residue on evaporation method

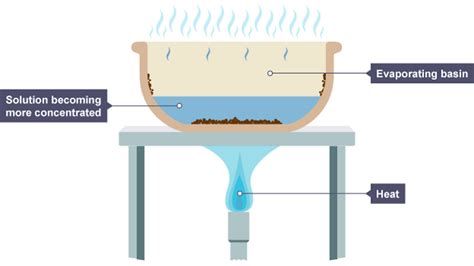

Summary of method. 2.1 A volume of filtered sample that will yield less than 200 mg residue is evaporated just to dryness on a steam bath. The residue is dried at 105°C for 2.0 h, cooled in a desiccator, and immediately weighed.

non volatile residue testing

ERT-01 Evaporation Residue Constant Weight Tester is professionally designed for the precisely quantitative determination of dissolved substances of containers and packaging films in food industry. Request a Quote View MoreGravimetric determination of NVR content measures solvent purity/surface residues to ensure quality and process efficiency. Non-Volatile Matter determination involves evaporating the .

This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, aerospace, and other industries. .ERT-01 Evaporation Residue Constant Weight Tester is professionally designed for the precisely quantitative determination of dissolved substances of table wares, containers, .This analysis determines the mass of the residue left behind when the water in the sample is evaporated at different temperatures.

1.1 This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, and related .

i-Resitest 8100 Evaporation Residue Constant Weight Tester is professionally designed for the precise mass determination of dissolved substances of table wares, containers, packaging . The NaOH they add to it is to prolong shelf life. And the reaction by which sodium hypochlorite is reduced to sodium chloride consumes protons, producing even more hydroxide, so it's indeed possible that residual alkali is .

100 degree evaporation residue

100 degree evaporation procedure

universal tensile testing machine instron

The Japanese Food Sanitation Act designates the evaporation residue test as a specification for plastics that intended to contact with foods. The test conditions and migration limits for oils and fatty foods were considered on the basis of the results obtained from the evaporation residue test according to the Japanese Act and the overall migration test into olive oil according to .

Nonvolatile residue (NVR), sometimes referred to as molecular contamination is the term used for . However, ASTM E595-84 testing has become standard practice for assessing NVR risk. Nonetheless, good quality control to verify the space . During the manual evaporation method, the mass of the molecular residue obtained from the NVR

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997).Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.Evaporation residue test (Overall migration test) Limit: 30 μg/ml (when using heptane, PE and PP ≤ 150, PS ≤ 240, PMP ≤ 120 μg/ml ) Determination: Weigh residue of migrant after drying and heating at 105°C for 2 hr. Test condition Food Simulant Temp(°C) Time(min) Normal(pH>5) water .

Going Deeper - Nonvolatile Residue - NVR Testing. While particulate contamination physically blocks openings and clearances, nonvolatile residue (NVR) causes issues through chemical means. . The Critical Role of Flash Evaporation in NVR Testing. A flash evaporator system enables key aspects of NVR testing essential for reliable and accurate . 1.1 This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, and related industries. This material is referred to as residue after evaporation (RAE). The range of the test method is from 0.001 μg/L (ppb) to 60 μg/L (ppb).

We found that during evaporation, droplets on the tested surfaces first shrink in height (constant contact radius mode) and then in diameter (constant contact angle mode) to form a thin liquid film, leaving behind residues of different types on the order of micrometers, as illustrated in Fig. 1.We either obtain a single residue, most likely a thin film or droplet, or .The TOC vials were placed open under an extractor hood to assist evaporation without inputting external contamination. Despite all these precautions, and in order to take account of potential carbon contamination appearing during sample evaporation, sample blanks were also prepared and left to evaporate beside the test samples.seconds at 31. /minute (4), and gas in the test tube is replaced by air. Note (3): Before removing the test tube, the water drops between the graduated test tube and the connecting portion of the evaporation cylinder shall be wiped off. Note (4): Methods of blowing the air into test tube shall be in accordance with Fig.6.

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997).Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.3.1 The test may be used to indicate compositional charac-teristics of emulsified asphalt. Evaporation residue may also be subjected to other characterization tests. 3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be .observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2:1960 ‘Rules for rounding off numerical values (revised)’. The number of significant places retained in the rounded off . Tests on residue: t ) Residue by evaporation, 60 percent, A4in 2) Penetration25°C/ 100g/ 80-150 5 sec 3 .

Categories: Evaporation Residue Testing Overview ERT-01 Evaporation Residue Constant Weight Tester is professionally designed for the precisely quantitative determination of dissolved substances of table wares, containers, packaging films, cans, tubes and other food-use equipments in different soaking solutions.MODEL : HGT 915 & 917: Gum Test; SPECIFICATION : Measure evaporation residue in aviation fuels, motor gasolines, and other volatile distillates. > The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of . The term “SAP” in the context of acetic acid glacial testing likely refers to the “Saponification Value” or “Saponification Acid Value.” The Acetic Acid Glacial Testing Procedure (SAP) saponification value is a measure of .

Residue from Evaporation Test Residue (c), percent T 59 63 Penetration, 25°C (77°F), 100 g, 5s, dmm T 49 60 150 Elastic Recovery, percent T 301 65 Solubility in Organic Solvent, percent T 44 97.5 (a) After standing undisturbed for 24 hours, the emulsion will be smooth and homogeneous throughout with no white, milky .

In geology there is a streak test where a mineral is rubbed on a alumina plate to create microscopic particles. The streak test often yields colors that are different than that of the "massive" specimen. . is there such case with a salt solution where hydrated salt version would not occur as the residue after evaporation, or vice versa with .

3.1.1 For deÞnitions of terms used in this test method, refer to Terminology D4175. 3.2 DeÞnitions of Terms SpeciÞc to This Standard: 3.2.1 existent gum, nÑthe evaporation residue of aviation fuels, without any further treatment. 3.2.2 solvent washed gum content, nÑ the residue remaining when the evaporation residue (see 3.2.3) has been .6.Now weigh each beakers along with the rods & residue. This will be in grams(A) CALCULATION. Residue, percent = 2 (A – B) where, A = mass of beaker, rod and residue, in g; and B = tare mass of beaker and rod, in g. For the accuracy of the result take the average of them in %. TESTS ON RESIDUE. From this emulsion residue we can perform the .

Evaporation residue test is to measure the dissolved part mass of materials in different solutions. By further analysis for evaporation residue, the safety of packaging materials can be greatly ensured. Contact Us! We can help you select .Cleaning validation procedures are carried out in order to assure that residues of cleaning agents are within acceptable limits after the cleaning process. Cleaning agents often consist of a mixture of various surfactants which are in a highly diluted state after the water rinsing procedure has been completed. This makes it difficult to find appropriate analytical methods that are sensitive . Residue on Evaporation Test (water analysis) : Evaporate 100 ml to dryness on a water bath and dry to constant weight at 105°C. The residue weighs not more than 1 mg (0.001%). Heavy Metals Test (water analysis) : Determined by Method D on 12 ml of a solution prepared in the following manner.

I SO 5277, Aromatic hydrocarbons - Determination of residue on evaporation. 1) I SO 5789, Fluorinated hydrocarbons for industrial use - Deter- mina tion of non-vola Me residue. 3 Principle Evaporation of a test portion on a water bath, and drying of the residue, if any, in an oven at 110 + 2 OC to constant mass. Then, the residue was stirred continuously at 155 °C until the residue surface was smooth and flat without bubbles, the temperature was increased and kept at 160 °C for 1 min. The appearances of base asphalt, SBS modified asphalt, SBS modified emulsified asphalt and evaporation residue were shown in Fig. 3.Evaporation Residue Tester can test the dissolving-out amount of test sample soaked in specified liquid. Applications. Applications. Applicable to tableware, food containers, packaging films, bags, cap sealing rubber pad, painted coating for inner wall of cans or tins, plant fiber container and so on made from polyethylene, polystyrene .Residues form on surfaces from droplet evaporation Figure 1. Example first and last frames showing the formation of (a) single residue and (b) multiple residues from single droplet evaporation on a coated glass substrate. (c) Schematic illustration of the evaporation curve which demonstrates how the droplet size changes over time. D p

Resultado da ABOUT OUT & LOUD & PROUD. Out & Loud & Proud 2023 builds on over 20 years of Australian and Indo-Pacific LGBTIQA+ choirs gathering to sing as one. By collaborating with the world’s biggest Pride event, OLP 2023 will be a choral festival unprecedented in its scope and reach. Out & Loud has .

bespoke Evaporation Residue Testing|100 degree evaporation residue